Polkemic has a very modern manufacturing facility with its own production halls, laboratory and a design and testing department.

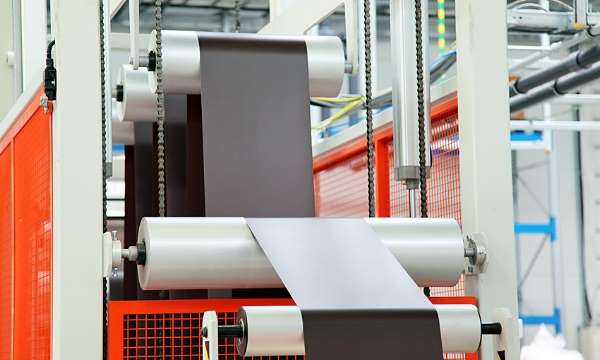

We produce edges and profiles from two of the most commonly used materials, PVC and ABS. Our products are made by exploiting the most modern technology in the field of twin-screw extruders and printing with the use of rotogravure and UV light drying techniques.

Our specialists are capable of creating the best suited design to meet your expectations. The exceptionally high quality tools used during the extrusion processes guarantee very precise dimensional tolerances.

Our designers and graphical technicians are able to design the right color and tone to suit your deepest desires. We are able, in just a short time, to create a custom matching for our client’s individual order where it is possible to custom match the color, structure and even the size of the edge band. By implementing the best inks and lacquers we can guarantee the highest quality and durability of the print as possible.

Polkemic’s profiles, from their introduction on the market, were considered to have an above average quality. A meticulous and inquisitive care to maintain constant, unchanging parameters of the components as well as continuously controlling the quality and accuracy of the extrusion of the final product we obtain by the implemented two-step control process. These goals are achieved by conducting strict laboratory quality controls within the company and also by entrusting the testing to external laboratories.

Thanks to the implementation of the most modern diagnostic devices, Polkemic is able to determine even the smallest deviation in the quality of the components delivered for production before the final product is even made from them. This procedure effectively eliminates the risk of producing profiles deviating from model parameters. Each and every stage of the edge production process is continuously monitored and controlled.

ul. T. Boya-Żeleńskiego 2a, Rzeszów

ul. T. Boya-Żeleńskiego 2a, Rzeszów +48 17 85 40 624

+48 17 85 40 624 biuro@polkemic.pl

biuro@polkemic.pl